I’ve read a lot of woodworking tips and tricks online, so much so, that it seems like I’m not seeing any new ones.

So I set out to make a useful collection of woodwork tricks that aren’t the typical ones you see online.

I hope you enjoy these and pick up at least one tip you haven’t seen before.

1. Measure Your Circular Saw

This first trick is ideal if you’re framing, or doing woodworking where a tolerance of ± 3mm (or 1/8 inch) is acceptable.

Measure the distance between your blade and both edges of the saw base plate. Then commit these measurements to memory. In my case it’s 4 inches on one side and an inch and an eighth on the other. This allows me to rip sheet goods (particularly plywood) to these measurements quickly and accurately without measuring or marking. I just set the saw up with the base plate parallel to the edge of the sheet and away I go!

You’ll be amazed how often you’ll use it. Taking an inch off a sheet of plywood when you’re framing a house is a very handy thing to be able to do quickly. Similarly, being able to rip plywood to the same thickness as a 2 x 4 without measuring or marking saves me a load of time.

2. Playing Cards as Spacers

This is a great way to evenly and accurately line up doors and drawer fronts. It’s so simple.

For example, if I’m fitting drawer fronts in a face frame cabinet: I offer up the drawer front and push it tight to one side of the opening. Then I jam as many cards as will fit into the other side of the opening. Let’s say I manage to get 10 cards in. Then I take the cards out and put 5 on the left and 5 on the right. (I follow the same process to space it top and bottom also.) Then I push the drawer front in and get it temporarily fixed with with double sided foam tape. Then I screw through the back of the drawer box into the drawer front.

It gives me perfect results every time!

3. Don’t Use Clamps– Use Masking Tape!

This trick works brilliantly for making mitred boxes. It’s pretty difficult to clamp a mitred box anyway! Lay your four pieces out flat with the outside faces of the box facing up. Line them up correctly and tape them together as per pics above.

Then flip the pieces over and glue inside your mitres. Fold them together and tape up the last remaining joint. This gives me perfectly aligned mitres every time!

4. Measure Internal Mitres Using Your Mitre Saw

Measuring and marking the internal edge of mitres is tricky . I tend to cut the first mitre, then lay the piece on my saw. I hook my tape onto the end of the saw and line up the internal edge with my tape. I can then easily pull the tape to where I need it and mark the inside of the other mitre.

5. Sand Your Hands

If you’re using wood filler and your hands get caked in the stuff, I take some medium grit sand paper and rub it off. It works brilliantly.

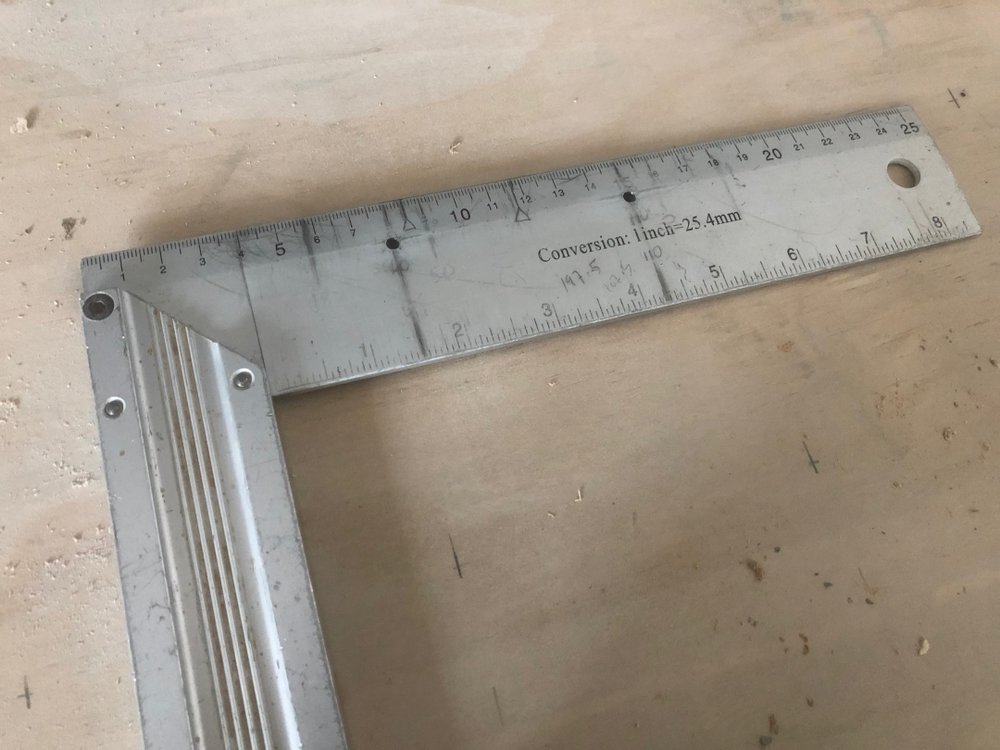

6. Drill Holes in Your Square

This is one of my favourite tricks. I use it for measurements I use every day. In my case, as you’ll see from my square above, I constantly have to mark pieces at two specific points every day. (The measurements are 40 mm & 110 mm if you can’t make them out!). This saves me having to adjust a combination square, or having to keep two combination squares. I also have an amazing square from Wolfcraft that does the same thing on a more professional level. But it’s a bit big for my liking. So, my battered old square with two strategically placed holes in it does the job perfectly.

7. L-Shaped Block for Marking Skirting Board

When you need to accurately mark skirting board, a small L-shaped block works a treat! It’s especially useful if the floor is running off a little. Get your piece of skirting board/base board lined up and in position. Hold the L-shaped block along the edge of your architrave and mark. This will give you the perfect mark, allowing you to make the perfect cut.

It’s a bit of a risk if you just mark it and cut it square. You may be a fraction out at the top or the bottom of your joint. This way your cut line is perfectly in line with your architrave.

8. Clothes Peg to Hold Panel Pins

I’ve got big, awkward fingers that really struggle with small pins when nailing by hand. I’ve been known to give my poor fingers a few blows of the hammer at times! A clothes peg kept in your tool bag solves this problem nicely.

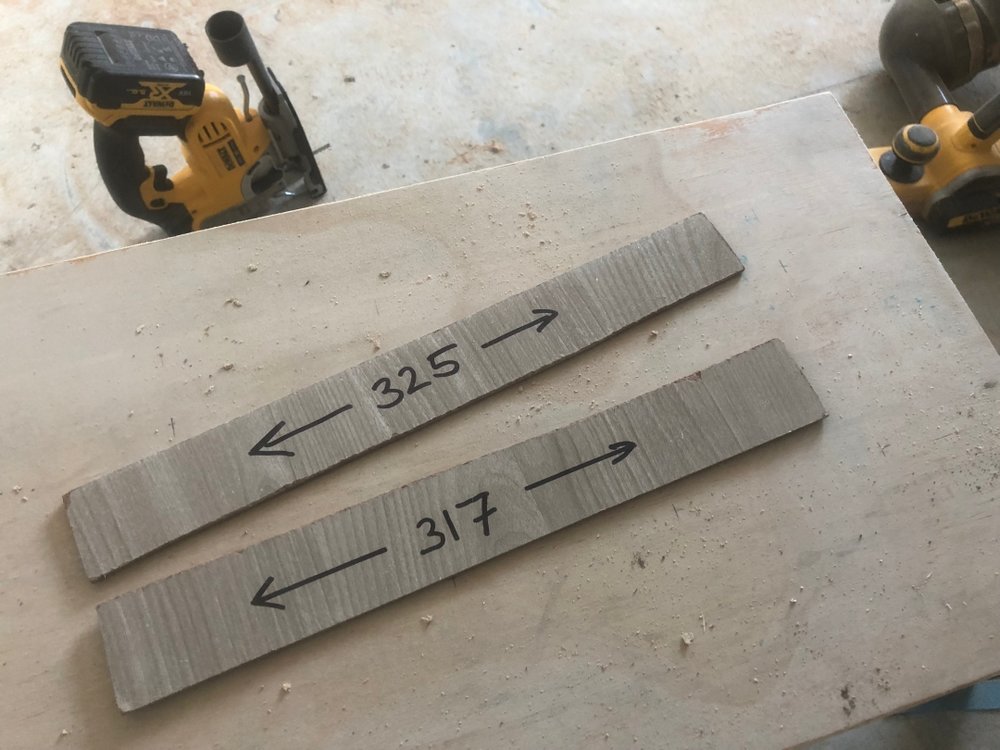

9. Use Story Sticks Instead of a Tape Measure

If I need to make a lot of repeat marks, and they need to be all exactly the same– a story stick is a great way to achieve this accuracy. I get some old bits of hardboard or 1/8” plywood and cut them to the size I need on my mitre saw. Using these to mark is far more accurate than trying to use a tape for every cut. I use these when spacing shelves in a cabinet where there is no line bore. Saves a ton of time marking, and is way more accurate.

P.S. If you liked this article, you may also like to get free and practical tips on woodworking techniques, business growth, productivity, and more in your inbox each week (you’ll also get the “How to Make a Living From Woodworking” PDF guide). Simply SIGN UP HERE to get exclusive access to a wealth of knowledge.

This post appeared first on https://www.sawdustetc.com